How to Diagnose and Repair Common Small Engine Problems

Understanding Small Engine Basics

Small engines are the power behind many of our everyday tools, from lawnmowers to chainsaws. Understanding the basics can help you diagnose and repair common problems. These engines typically operate using a simple four-stroke cycle, involving intake, compression, power, and exhaust. Recognizing the symptoms of engine trouble is the first step in addressing any issues.

The most common small engine problems include difficulty starting, loss of power, or unusual noises. Often, these issues are linked to the fuel system, spark plugs, or air filters. Identifying the root cause can save both time and money by allowing targeted repairs.

Diagnosing Engine Problems

Checking the Fuel System

A faulty fuel system is a frequent culprit in engine troubles. Begin by examining the fuel itself; old or contaminated fuel can lead to starting issues. Ensure that the fuel tank is clean and filled with fresh gasoline. Next, inspect the fuel lines for any signs of wear or damage.

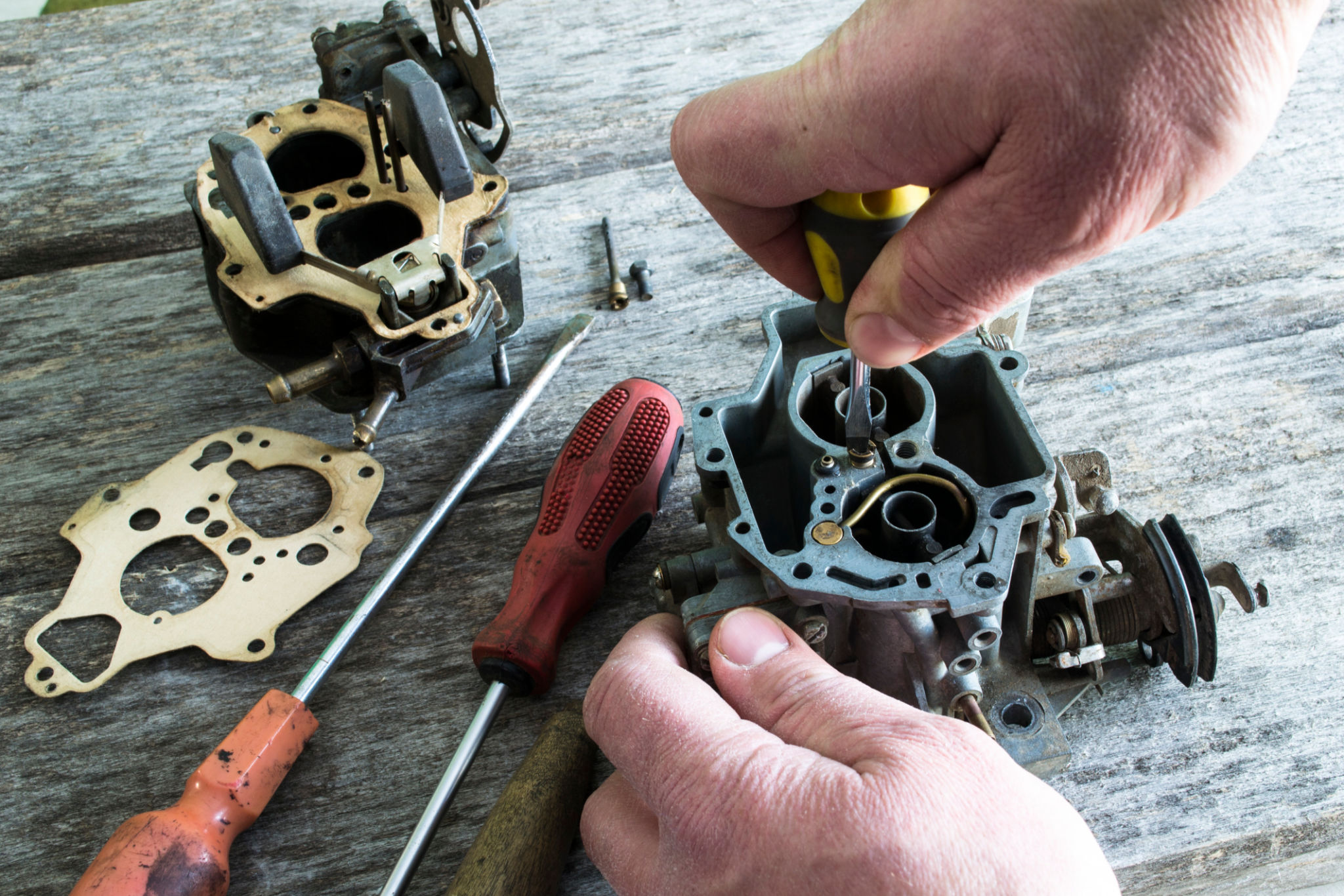

If the engine still struggles to start, consider cleaning or replacing the carburetor. The carburetor is responsible for mixing air with fuel before it enters the engine. Dirt or debris can clog this component, hindering performance.

Inspecting the Spark Plug

The spark plug is another critical element to check when diagnosing engine problems. Over time, spark plugs can become fouled with carbon deposits, preventing them from firing properly. Remove the spark plug and inspect it for any signs of damage or excessive wear.

If necessary, clean the spark plug using a wire brush or replace it with a new one. Always ensure that the spark plug gap is set to the manufacturer's specifications for optimal performance.

Repairing Common Issues

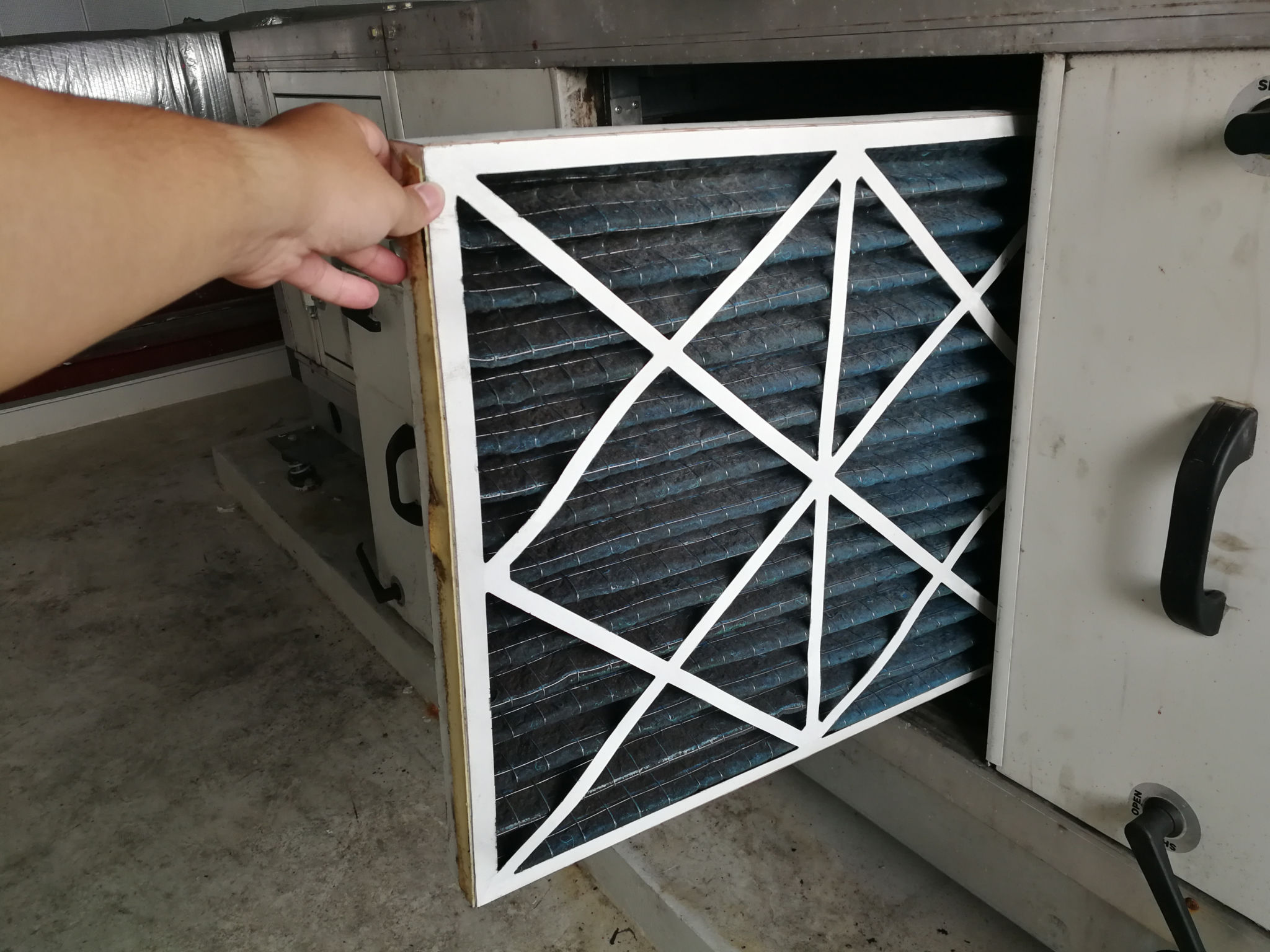

Replacing Air Filters

A dirty air filter can restrict airflow to the engine, leading to reduced performance and increased fuel consumption. Regularly check and replace air filters to keep your engine running smoothly. Most air filters are easy to access and replace without specialized tools.

Tightening Loose Parts

Vibration from regular use can cause screws and bolts to loosen over time. Periodically inspect all visible fasteners on your small engine and tighten them as needed. This simple maintenance step can prevent more significant issues down the road.

Additionally, examine belts and hoses for any signs of wear or cracking. Replacing these components before they fail can save you from more extensive repairs later.

Preventative Maintenance Tips

Regular maintenance is key to extending the life of your small engine. Follow these tips to prevent common problems:

- Change the oil regularly to ensure proper lubrication.

- Keep your engine clean and free of debris.

- Store your equipment in a dry place to prevent rust and corrosion.

By keeping up with maintenance and addressing small issues promptly, you'll ensure that your small engine remains reliable for years to come.