DIY Small Engine Repair: Common Issues and How to Fix Them

Understanding Your Small Engine

Small engines are the heart of many household machines, powering everything from lawnmowers to chainsaws. Knowing how to troubleshoot and repair these engines can save you time and money. Whether you're dealing with a lawnmower that won't start or a chainsaw that's lost its power, understanding the basics of small engine repair is crucial.

Before diving into repairs, it's essential to understand the basic components of small engines. Most consist of a carburetor, spark plug, air filter, fuel system, and ignition coil. When issues arise, they usually involve one of these critical parts.

Common Starting Issues

Engine Won't Start

If your engine refuses to start, the first step is to check the fuel. Ensure there's enough fuel in the tank and that it's not old or contaminated. Stale gas can cause starting problems, so if the fuel is old, draining and replacing it might solve the issue.

Next, inspect the spark plug. Remove it and check for signs of wear or damage. A faulty spark plug can prevent the engine from firing. If it's dirty or corroded, clean it with a wire brush or replace it if necessary.

Power Loss and Performance Drops

Engine Loses Power

When an engine loses power during operation, it often indicates a problem with the air filter or carburetor. A clogged air filter restricts airflow, leading to poor performance. Remove the air filter and clean it, or replace it if it's too dirty.

The carburetor controls the mixture of air and fuel that's sent to the engine. If it's clogged or improperly adjusted, it can lead to power loss. Cleaning the carburetor or adjusting the mixture screws can often restore optimal performance.

Unusual Noises and Vibrations

Loud Noises or Excessive Vibration

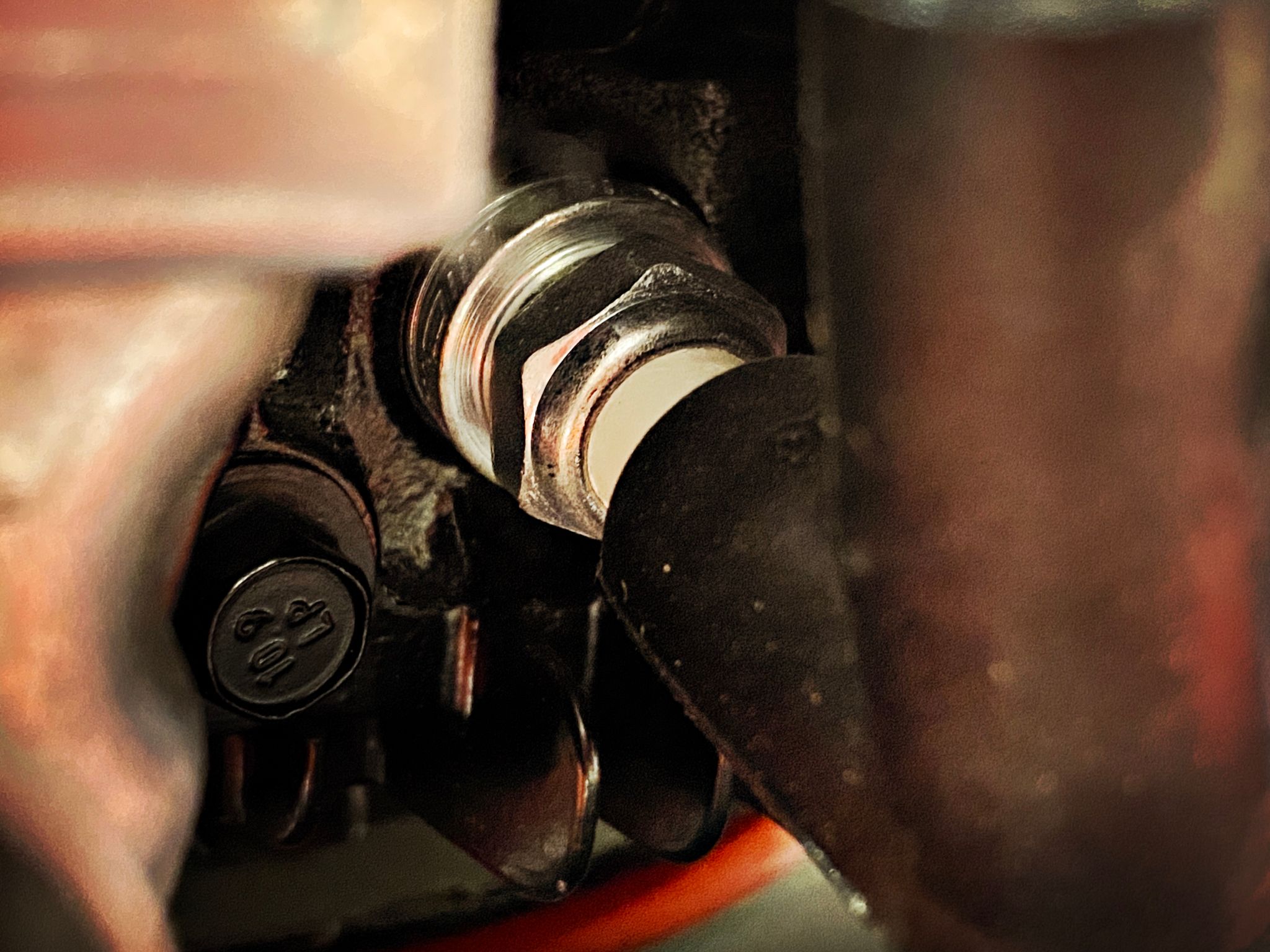

If your small engine is making unusual noises or vibrating excessively, it could be due to loose parts or a misaligned blade. Start by checking all screws and bolts to ensure they're tight. Loose components can cause rattling noises during operation.

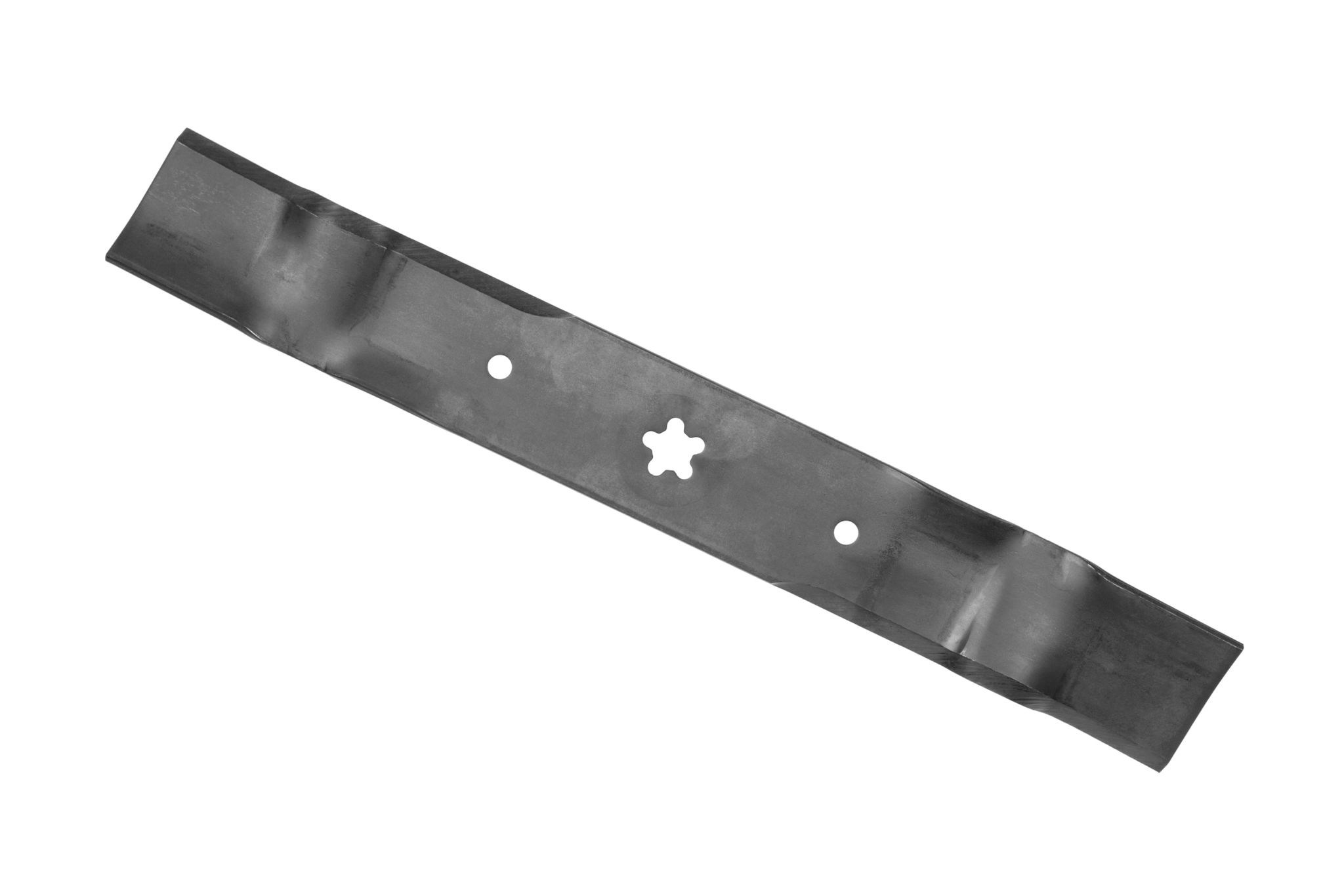

For equipment like lawnmowers, inspect the blades for damage or misalignment. Blades should be balanced and sharp; otherwise, they can cause vibrations. Replacing damaged blades or having them professionally sharpened can often solve this problem.

Routine Maintenance for Longevity

Regular maintenance is key to preventing many common small engine problems. Make it a habit to change the oil every season and inspect the fuel system for leaks or cracks. Keeping the air filter clean and replacing it when needed ensures your engine runs efficiently.

Additionally, store your equipment in a dry place and use fuel stabilizers if you're storing engines for an extended period. This simple routine can significantly extend the life of your small engines.

Troubleshooting Tips

Troubleshooting small engines might seem daunting at first, but with patience and practice, you'll become more comfortable. Start by identifying the symptoms and systematically checking each potential cause. Keep a toolkit with essential tools like screwdrivers, pliers, and wrenches handy for quick repairs.

Lastly, always refer to the manufacturer's manual for specific instructions related to your equipment model. This guide can provide valuable insights into solving particular issues effectively.