Common Small Engine Repair Mistakes and How to Avoid Them

Understanding Common Small Engine Repair Mistakes

Small engines power many of the tools and machines we rely on every day, from lawnmowers to chainsaws. However, when they break down, fixing them can sometimes be more complicated than expected. Understanding the common repair mistakes can help you avoid costly errors that could lead to further damage.

Neglecting Regular Maintenance

One of the most frequent mistakes is neglecting regular maintenance. Small engines require routine checks and services to function optimally. Ignoring tasks like changing the oil, replacing the air filter, and checking the spark plug can lead to premature wear and tear.

Solution: Set up a regular maintenance schedule. Refer to the manufacturer's manual for specific maintenance intervals and stick to them. This proactive approach can prevent many common issues before they arise.

Using Incorrect Fuel

Another common error is using the wrong type of fuel. Many small engines require specific fuel types and mixing ratios, particularly two-stroke engines. Using the incorrect fuel can cause engine knocking, poor performance, and even permanent damage.

Solution: Always check the fuel requirements specified by the manufacturer. Use high-quality fuel and mix it correctly if needed. Storing fuel properly and using it within its shelf life is essential to maintaining engine health.

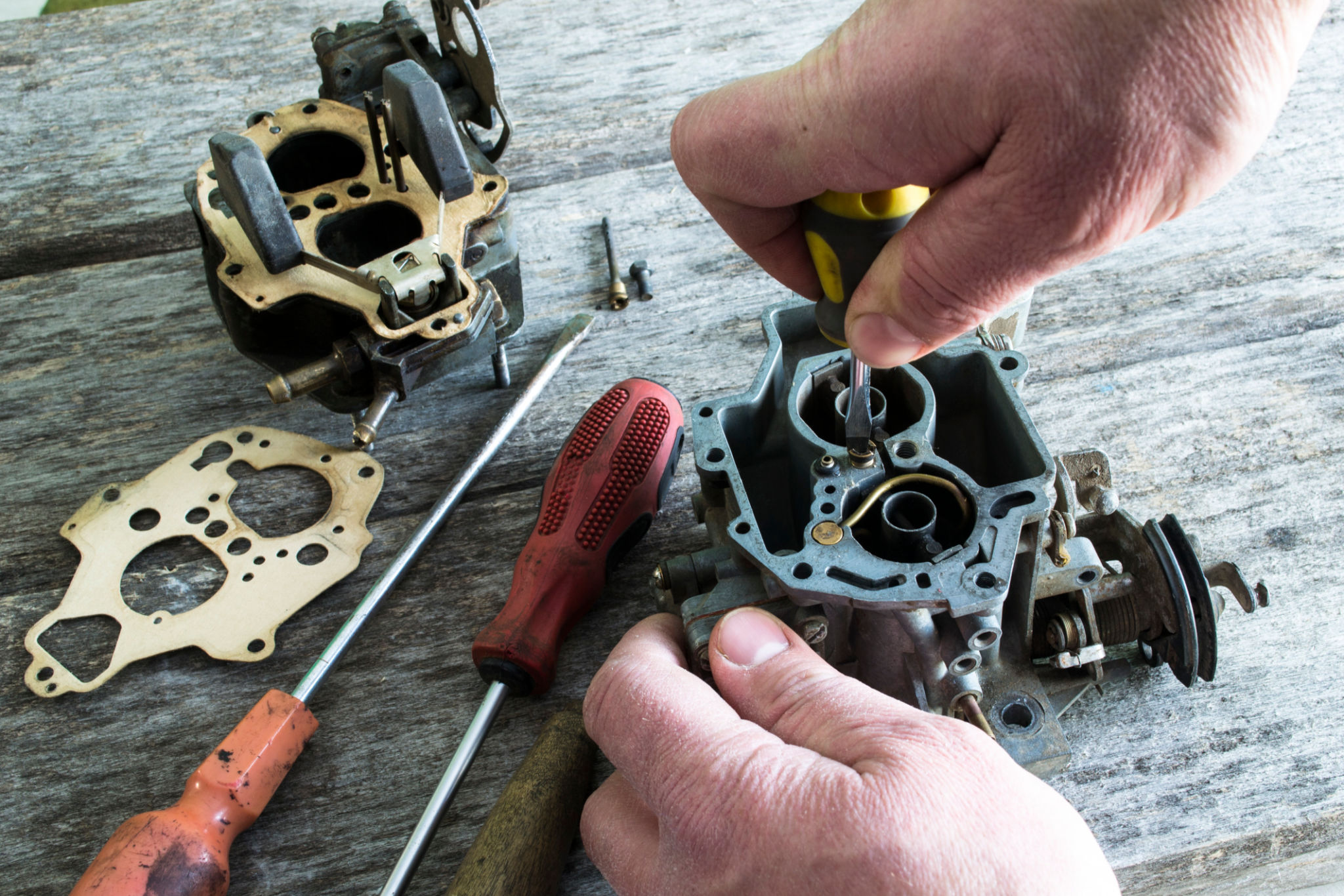

Overlooking Air Filter and Carburetor Issues

The air filter and carburetor are crucial components of a small engine. A clogged air filter can restrict airflow, causing poor performance, while carburetor issues can lead to starting problems and inefficient fuel use.

Solution: Regularly inspect and clean or replace the air filter as needed. If you suspect carburetor issues, cleaning it thoroughly can often resolve performance problems. If unsure, consult with a professional to avoid further complications.

Improper Storage Practices

Improper storage of small engines can lead to numerous problems, especially during off-seasons. Leaving fuel in the tank for extended periods without proper stabilizers can result in gum deposits that clog the system.

Solution: Before storing your equipment for long periods, drain the fuel tank or add a fuel stabilizer. Store the engine in a dry place, and follow any additional storage instructions provided by the manufacturer.

Misdiagnosing Engine Problems

Attempting to repair an issue without properly diagnosing it is a common mistake that can lead to unnecessary repairs or replacements. Many symptoms can have multiple causes, making accurate diagnosis crucial.

Solution: Take the time to thoroughly assess the problem before starting repairs. Consult repair manuals or online resources, and don't hesitate to seek professional advice if needed. Proper diagnosis saves time and money in the long run.

In conclusion, by being aware of these common small engine repair mistakes and taking proactive steps to avoid them, you can ensure that your equipment runs smoothly for years to come. Regular maintenance, proper fuel management, and careful problem diagnosis are key strategies in keeping small engines in top condition.