A Beginner's Guide to Preventative Maintenance for Small Engines

Understanding the Importance of Preventative Maintenance

Preventative maintenance is crucial for ensuring the longevity and efficiency of small engines, whether they power lawnmowers, generators, or other essential equipment. Regular maintenance not only keeps engines running smoothly but also helps prevent costly repairs and unexpected breakdowns. By implementing a consistent maintenance schedule, you can save both time and money in the long run.

Basic Tools and Supplies Needed

Before diving into maintenance tasks, gather the necessary tools and supplies. Commonly required items include a wrench set, screwdrivers, spark plug wrench, oil filter wrench, and a collection pan for old oil. Additionally, you'll need engine oil, air filters, fuel stabilizer, and spark plugs. Having these tools on hand will make the process more efficient and less stressful.

Regular Oil Changes

One of the most important aspects of small engine maintenance is regular oil changes. Engine oil lubricates the moving parts, reducing friction and wear. To perform an oil change, start the engine to warm up the oil, making it easier to drain. Turn off the engine and remove the oil cap and drain plug. Allow the old oil to completely drain into a pan before replacing it with fresh oil.

Cleaning or Replacing Air Filters

Air filters play a vital role in keeping dirt and debris out of the engine. A clogged air filter can reduce efficiency and lead to engine damage. Check air filters regularly and clean them if they are reusable. If they are beyond cleaning or are disposable, replace them with new ones according to the manufacturer's specifications.

Spark Plug Inspection and Replacement

Spark plugs are essential for starting the engine and ensuring smooth operation. Over time, they can become dirty or worn out, affecting engine performance. Inspect spark plugs every season and replace them if necessary. A new spark plug can improve fuel efficiency and reduce emissions, contributing to better engine health.

Fuel System Maintenance

Maintaining the fuel system is crucial for optimal engine performance. Use a fuel stabilizer to prevent fuel degradation, especially if the engine will be stored for an extended period. Additionally, inspect fuel lines for cracks or leaks and replace them if needed to avoid potential issues.

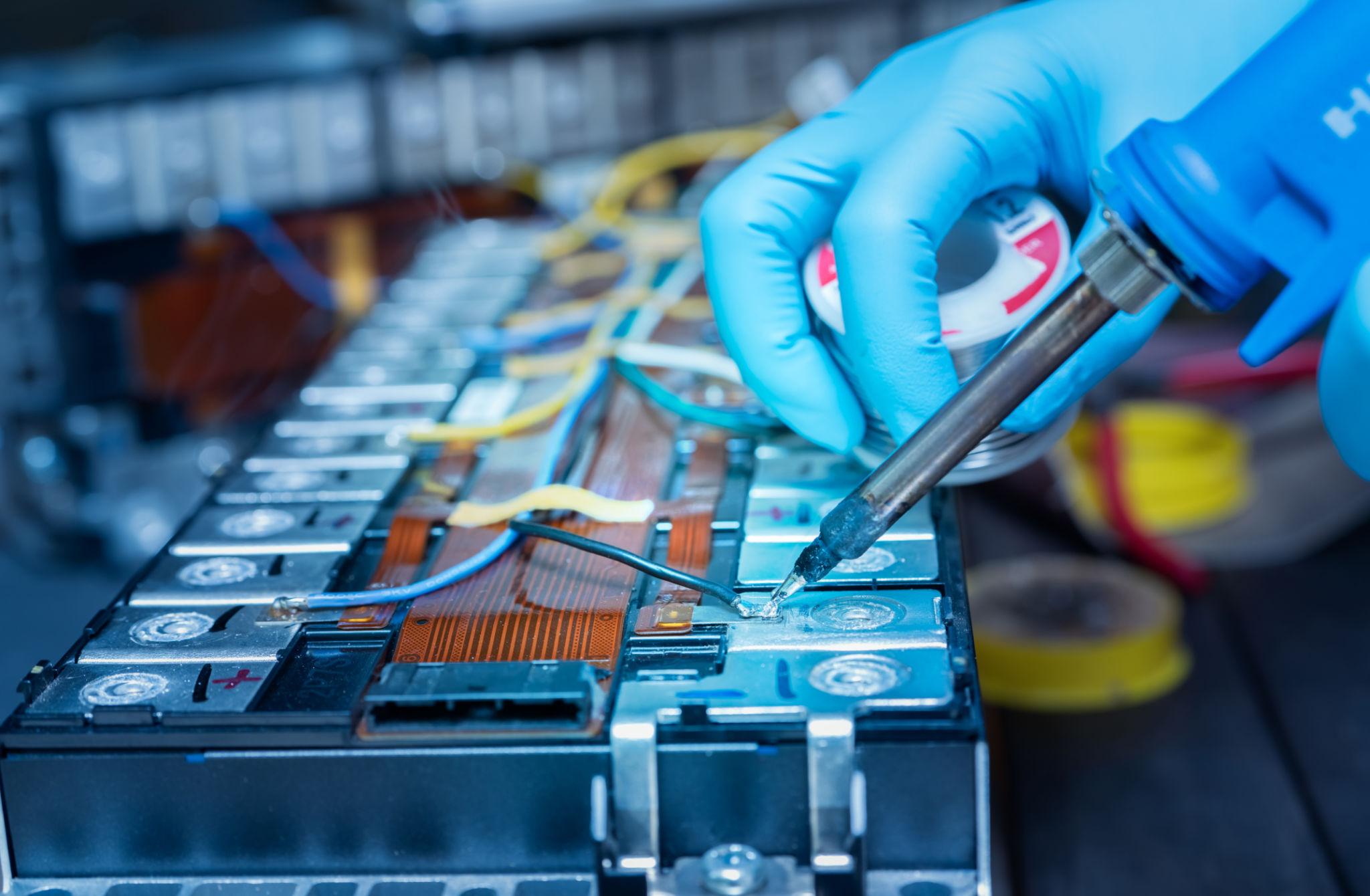

Battery Care and Storage Tips

If your small engine uses a battery, ensure it is properly maintained. Clean battery terminals to prevent corrosion and check charge levels regularly. When storing equipment for an off-season, remove the battery and store it in a cool, dry place to prolong its life.

Final Thoughts on Preventative Maintenance

Implementing a preventative maintenance routine is essential for keeping small engines in top condition. By following these guidelines, you can extend the lifespan of your equipment and ensure it operates reliably when you need it most. Remember, consistency is key—regular checks and maintenance tasks will save you from potential headaches down the line.